PRODUCT PARAMETERS

Description

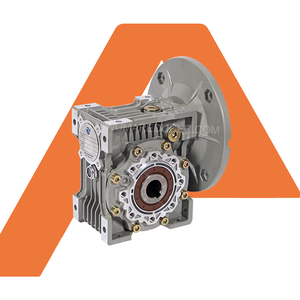

Introduction of Gearboxes High Speed Nema 34 Used Worm Drive Gearboxes With Motor For Conveyor Crawler Generator

Gearboxes High Speed Nema 34 Used Worm Drive Gearboxes With Motor For Conveyor Crawler Generator, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.Gearboxes High Speed Nema 34 Used Worm Drive Gearboxes With Motor For Conveyor Crawler Generator is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of Gearboxes High Speed Nema 34 Used Worm Drive Gearboxes With Motor For Conveyor Crawler Generator

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(Gearboxes High Speed Nema 34 Used Worm Drive Gearboxes With Motor For Conveyor Crawler Generator)

Specification of Gearboxes High Speed Nema 34 Used Worm Drive Gearboxes With Motor For Conveyor Crawler Generator

High-speed NEMA 34 worm drive transmissions with incorporated electric motors are crafted for requiring applications such as conveyor systems, crawlers, and generators, supplying a mix of accuracy, toughness, and power. These transmissions are created with a NEMA 34 stepper or servo electric motor interface, making sure compatibility with industry-standard installing arrangements. The electric motor operates at voltages varying from 24V DC to 230V AIR CONDITIONING, providing continuous torque outcomes in between 5 Nm to 25 Nm, with peak torque capabilities up to 50 Nm for high-load circumstances. The integrated worm equipment system provides a right-angle drive option, optimizing room performance in portable arrangements. Gear proportions typically extend from 5:1 to 60:1, enabling exact speed control from 10 RPM to 1,500 RPM, depending upon the application requirements. The worm wheel is crafted from hardened phosphor bronze or stainless steel for wear resistance, coupled with a high-strength alloy steel worm shaft, making certain smooth procedure under continuous high-speed loads. Real estate is constructed from lightweight, corrosion-resistant light weight aluminum with integrated cooling fins to improve warmth dissipation throughout prolonged use. Input and result shafts are precision-machined, including keyway or dual-dowel pin setups for secure combining. These devices sustain bidirectional procedure and include sealed bearings to stop contamination in rough settings, rated for IP54 or higher defense. Lubrication is pre-filled with high-temperature artificial grease, reducing upkeep demands. Thermal overload protection and anti-backlash modifications are typical, enhancing reliability in recurring or high-cycle applications. Personalization choices consist of personalized shaft dimensions, encoder comments combination, and particular equipment proportions. Ideal for conveyor crawlers and generator drives, these gearboxes master situations requiring high torque, low noise, and very little resonance. Conformity with ISO 9001 and CE standards makes certain quality and security. Backed by a 12-month warranty, they are a durable solution for commercial automation, product handling, and power systems demanding accuracy movement control.

(Gearboxes High Speed Nema 34 Used Worm Drive Gearboxes With Motor For Conveyor Crawler Generator)

Applications of Gearboxes High Speed Nema 34 Used Worm Drive Gearboxes With Motor For Conveyor Crawler Generator

High-speed NEMA 34 worm drive gearboxes incorporated with motors are flexible power transmission services developed for demanding commercial applications. These compact, high-torque systems integrate the efficiency of NEMA 34 stepper or servo motors with the longevity of worm gear reducers, making them excellent for conveyor systems, spider devices, and generator drives. Their robust design guarantees reliable performance in atmospheres calling for precision, high-speed procedure, and heavy tons handling.

In conveyor systems, these transmissions excel at controlling product circulation with smooth, consistent activity. The worm drive’s self-locking function protects against back-driving, making sure safety during unexpected stops or likely operations. High-speed capacities make it possible for rapid product transfer in production, product packaging, or logistics, while the NEMA 34 electric motor’s torque maintains efficiency under variable loads. Their small footprint conserves room in tight layouts, and the hardened steel worm equipments resist wear in dirty or high-temperature settings.

For crawler-driven machinery, such as farming devices, building and construction vehicles, or automated directed automobiles (AGVs), these gearboxes deliver precise speed decrease and torque reproduction. The NEMA 34 electric motor’s responsiveness permits accurate speed control, vital for browsing irregular terrain or carrying out recurring tasks. The worm drive’s shock absorption decreases resonance, extending component life in rugged atmospheres.

In generator applications, the gearbox-motor assembly acts as a reliable power transmission unit, transforming power into electrical output. High-speed procedure guarantees ideal generator RPM, while the worm equipment’s effectiveness lowers power loss. This configuration is suitable for backup power systems, renewable energy installments, or mobile generators requiring portable, high-performance components.

Key benefits consist of low upkeep because of the worm gear’s oil-retention layout and the electric motor’s long life span. The NEMA 34 standard ensures compatibility with commercial control systems, simplifying combination. Light weight aluminum or cast iron housing alternatives provide rust resistance, and customizable gear proportions enable tailoring to particular speed-torque needs.

Industries such as vehicle, food processing, mining, and renewable energy benefit from these gearboxes’ flexibility. Whether driving a conveyor belt in a factory, powering a spider in harsh terrain, or maintaining generator result, high-speed NEMA 34 worm drive transmissions with motors supply a resilient, reliable service for high-performance automation and power transmission requirements.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Gearboxes High Speed Nema 34 Used Worm Drive Gearboxes With Motor For Conveyor Crawler Generator

What are the primary applications of High Speed Nema 34 Worm Drive Gearboxes with Motor? These gearboxes are ideal for conveyor systems, crawler-based machinery, and industrial generators requiring high torque and precision. They’re commonly used in manufacturing, material handling, mining, and agriculture for tasks like moving heavy loads, powering tracked equipment, or driving auxiliary generator components. Their compact design and durability make them suitable for harsh environments with limited space.

What advantages do worm drives offer in these gearboxes? Worm drives provide high torque multiplication, smooth operation, and a self-locking mechanism that prevents back-driving, enhancing safety in vertical or inclined applications. Their compact design allows for efficient power transmission in tight spaces, while the hardened steel construction of the worm and gear ensures long-term durability and resistance to wear, even under continuous heavy loads.

Why is the Nema 34 motor standard for these gearboxes? The Nema 34 frame is a widely adopted industrial standard, ensuring compatibility with a range of motors and controllers. It supports high torque (typically up to 20 Nm) and speeds suitable for demanding applications. The motor’s robust construction pairs well with worm gearboxes, delivering reliable performance in high-vibration or high-duty-cycle environments like conveyors and crawlers.

What maintenance do these gearboxes require? Regular lubrication of the worm gear is critical to minimize friction and wear. Use high-quality grease or oil as specified by the manufacturer, typically every 1,000–2,000 operational hours. Inspect seals for leaks, check for unusual noise or vibration, and ensure motor connections remain secure. These units are generally low-maintenance but benefit from periodic professional servicing in extreme conditions.

What load and speed capabilities do these gearboxes have? High Speed Nema 34 Worm Drive Gearboxes typically handle input speeds up to 3,000 RPM, with output speeds adjustable via gear ratios (commonly 10:1 to 60:1). They support continuous torque outputs ranging from 50 Nm to over 300 Nm, depending on the configuration. Always verify the specific model’s ratings to ensure compatibility with your motor and application demands.

(Gearboxes High Speed Nema 34 Used Worm Drive Gearboxes With Motor For Conveyor Crawler Generator)

REQUEST A QUOTE

RELATED PRODUCTS

Industrial High Torque S Series Helical Gearbox Gear Reducer Planetary Gear For Concrete Mixer

PN16 Wafer Type Ductile Iron Gearbox Butterfly Valve DN600

Right Angle IP69K 0.18KW 0.24HP Stainless Gearbox Nmrv040 Worm Gearbox Water Proof Sus304 Variable Gear Stainless Steel Gearbox

High Quality Manual gearbox Ductile Iron F14 DIN EN Series Soft Seal Double Eccentric Flanged Butterfly Valve

Factory Direct Auto Parts Transmission Assembly 1701010LE420 JAC Jianghuai Light Truck Gearbox