PRODUCT PARAMETERS

Description

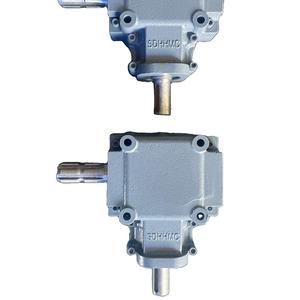

Introduction of 200~1000 Rpm MB Series Speed Variator Reduction gearbox

200~1000 Rpm MB Series Speed Variator Reduction gearbox, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.200~1000 Rpm MB Series Speed Variator Reduction gearbox is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of 200~1000 Rpm MB Series Speed Variator Reduction gearbox

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(200~1000 Rpm MB Series Speed Variator Reduction gearbox)

Specification of 200~1000 Rpm MB Series Speed Variator Reduction gearbox

The MB Collection Speed Variator Reduction Transmission is developed to supply accurate speed control and dependable torque transmission for industrial applications needing variable result rates in between 200 and 1000 RPM. This robust gearbox integrates a rate variator with a decrease equipment mechanism, making it possible for seamless modification of rotational speed while preserving optimum power effectiveness. It is crafted for longevity, with a compact layout ideal for combination into machinery such as conveyors, mixers, agitators, and handling tools. The gearbox supports bidirectional operation and works with electrical motors, hydraulic systems, or combustion engines. Trick specifications include a torque capability varying from 50 Nm to 1500 Nm, relying on the model, and reduction ratios from 5:1 to 30:1. The real estate is built from high-strength cast iron or light weight aluminum alloy, making certain resistance to use, rust, and mechanical tension. Gears are precision-machined from solidified steel for smooth procedure and expanded service life. Input and outcome shafts are dynamically balanced to reduce resonance and sound, also at high loads. The variator device uses a mechanical or digital control system for stepless speed adjustment within the specified RPM range, enabling drivers to fine-tune performance without stopping the machinery. Lubrication is maintenance-free or calls for minimal periodic checks, thanks to sealed bearings and oil-bath lubrication systems. The gearbox includes numerous installing options, consisting of flange, foot, or shaft-mounted arrangements, for flexible installment. Thermal protection and overload safeguards are incorporated to stop damages under severe conditions. Ambient operating temperature levels vary from -10 ° C to 50 ° C, with optional coatings or seals available for rough atmospheres. Input power rankings cover 0.5 kW to 30 kW, fitting diverse motor dimensions. Backlash is kept listed below 20 arc-min for accuracy applications. Personalized alternatives include unique shaft dimensions, anti-corrosion treatments, and IP65-rated rooms for dirt and dampness resistance. Compliance with global requirements such as ISO 9001 and CE certification guarantees quality and safety. The MB Series is ideal for sectors consisting of food handling, product packaging, textiles, and material handling, using a cost-efficient service for stabilizing rate irregularity and mechanical power transmission.

(200~1000 Rpm MB Series Speed Variator Reduction gearbox)

Applications of 200~1000 Rpm MB Series Speed Variator Reduction gearbox

The MB Series Rate Variator Reduction Gearbox, running within a variety of 200– 1000 RPM, is a flexible and durable part developed to enhance performance in commercial applications calling for exact rate control and high torque result. Its flexible speed capacities make it suitable for machinery that requires adaptability, effectiveness, and dependability across diverse sectors. In conveyor systems, the gearbox guarantees smooth material handling by readjusting belt rates to match production demands, whether in food processing, packaging, or mass product transportation. This versatility minimizes bottlenecks and boosts functional efficiency. For blending and agitation equipment, such as in chemical, pharmaceutical, or paint manufacturing, the MB Series supplies constant torque at variable rates, allowing uniform blending of products with varying viscosities while preventing electric motor overload. In the building and agriculture sectors, the gearbox drives equipment like concrete mixers, crushers, or harvesters, providing high torque at reduced rates to handle hefty loads and tough products without jeopardizing resilience. Its sealed design additionally withstands messy or damp atmospheres, guaranteeing durability. Packaging equipment benefits from the specific RPM control, enabling accurate filling, sealing, and labeling procedures. The transmission’s portable design and energy-efficient operation decrease downtime and maintenance expenses, making it an affordable option for computerized production lines. Furthermore, in fabric manufacturing, it powers rotating and weaving makers, preserving thread stress and material high quality through flexible rate settings. The megabytes Collection is engineered with high-grade products and precision gears, making certain quiet operation, minimal vibration, and resistance to wear. Its compatibility with various motor types and easy assimilation into existing systems further enhance its appeal. Whether in food handling, heavy sector, or automation, the megabytes Collection Rate Variator Reduction Transmission supplies performance, flexibility, and integrity, making it an important part for enhancing productivity and minimizing functional expenses.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of 200~1000 Rpm MB Series Speed Variator Reduction gearbox

What is the MB Series Speed Variator Reduction Gearbox? The MB Series is a compact, durable gearbox designed to control output speed between 200–1000 RPM while increasing torque. It combines a speed variator for adjustable speed control and a reduction gearbox to optimize power transmission. Ideal for industrial machinery, it ensures smooth operation, precise speed adjustments, and reliable performance under varying loads.

What applications is the MB Series suitable for? This gearbox is widely used in conveyors, mixers, packaging equipment, agricultural machinery, and material handling systems. Its adjustable RPM range makes it versatile for processes requiring variable speeds, such as blending, lifting, or feeding operations. It’s compatible with electric motors and suits environments demanding consistent torque and speed flexibility.

What maintenance does the MB Series require? The gearbox is designed for low maintenance. Regularly check oil levels (if oil-lubricated) and replace lubricant every 6–12 months, depending on usage. Ensure seals and gears are free from debris. For grease-lubricated models, replenish grease annually. Inspect for unusual noise or vibration, which may indicate wear. No complex disassembly is needed for routine upkeep.

How efficient is the MB Series gearbox? The MB Series achieves 92–95% efficiency due to precision-engineered helical or worm gears (depending on the model), minimizing energy loss. High-quality bearings and rigid housing reduce friction and heat generation, ensuring optimal power transfer. Efficiency remains stable across the 200–1000 RPM range, even under heavy loads.

Can the MB Series be customized for specific needs? Yes. Manufacturers often offer customization for mounting positions, shaft sizes, and flange types. Gear ratios, input power ratings, and optional accessories like cooling fans or encoders can be tailored. Custom paint, sealing (e.g., IP65 for dust/water resistance), or material upgrades (e.g., stainless steel) are available for harsh environments. Confirm requirements with the supplier for bespoke solutions.

(200~1000 Rpm MB Series Speed Variator Reduction gearbox)

REQUEST A QUOTE

RELATED PRODUCTS

PLF Series High Quality Planetary Gears Precision Planetary Gear Boxes Planetary gearbox

32mm dc micro planetary gearbox 395 dc electric gear motor for blind

Custom Heavy Excavator Gearbox Main Drive Helical Large Pinion Wheel Shaft Forging Steel Large Gear And Shaft Assembly

KL016004 New Gearbox Core Component for Container Lifting Transport System in Manufacturing Plants Material Handling Equipment

Special Vehicle Dump Truck G Gearbox Customized Pto Power Take Off