PRODUCT PARAMETERS

Description

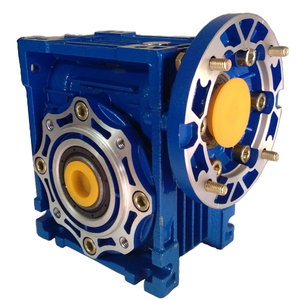

Introduction of KL016004 New Gearbox Core Component for Container Lifting Transport System in Manufacturing Plants Material Handling Equipment

KL016004 New Gearbox Core Component for Container Lifting Transport System in Manufacturing Plants Material Handling Equipment, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.KL016004 New Gearbox Core Component for Container Lifting Transport System in Manufacturing Plants Material Handling Equipment is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of KL016004 New Gearbox Core Component for Container Lifting Transport System in Manufacturing Plants Material Handling Equipment

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(KL016004 New Gearbox Core Component for Container Lifting Transport System in Manufacturing Plants Material Handling Equipment)

Specification of KL016004 New Gearbox Core Component for Container Lifting Transport System in Manufacturing Plants Material Handling Equipment

The KL016004 Transmission Core Part is a crucial component created for container lifting and transportation systems in manufacturing plants, making sure effective material managing procedures. This high-performance element is engineered to deliver sturdiness, accuracy, and integrity under heavy-load problems. Built from premium-grade alloy steel and heat-treated for improved stamina, it withstands wear, deterioration, and mechanical tension, extending life span in demanding industrial environments. The transmission core includes a modular layout enhanced for seamless integration with container lifting equipment, consisting of stackers, cranes, and automated assisted lorries (AGVs). Trick requirements include a maximum torque capability of 12,500 Nm, sustaining lots capacities approximately 45 metric tons, making it appropriate for hefty container transportation. The equipment ratio is configurable between 15:1 and 25:1, allowing customization for speed-torque equilibrium based upon operational needs. Precision-machined helical gears make sure smooth power transmission with minimal noise and vibration, boosting operator comfort and system durability. The element runs efficiently throughout a temperature level variety of -20 ° C to 120 ° C, with a sealed real estate ranked IP65 for protection against dust, dampness, and pollutants. Lubrication is kept using an integrated oil-bath system, decreasing upkeep intervals and ensuring constant performance. Compatibility with variable frequency drives (VFDs) and servo motors allows specific rate control, crucial for automated product handling procedures. Safety and security attributes include overload defense, anti-backlash systems, and thermal sensors to stop overheating. The KL016004 is tested to fulfill ISO 6336 and AGMA 2001 criteria, ensuring dependability in continuous-duty cycles. Its small dimensions (L450mm x W320mm x H280mm) and light-weight design (approx. 85 kg) assist in very easy setup and retrofitting into existing systems. Applications consist of port logistics, auto assembly lines, and stockroom automation. Backed by a 24-month warranty, this gearbox core element makes sure reduced downtime, reduced energy usage, and enhanced operational effectiveness for commercial product taking care of systems.

(KL016004 New Gearbox Core Component for Container Lifting Transport System in Manufacturing Plants Material Handling Equipment)

Applications of KL016004 New Gearbox Core Component for Container Lifting Transport System in Manufacturing Plants Material Handling Equipment

The KL016004 New Gearbox Core Part is a high-performance advancement crafted to enhance container lifting and transportation systems within producing plants. Created for sturdiness, precision, and effectiveness, this gearbox component boosts the integrity of product handling tools, making it possible for smooth procedures popular industrial environments. Its advanced engineering addresses the difficulties of heavy-load monitoring, recurring movement, and power usage, making it an important upgrade for modern-day manufacturing facilities.

** Secret Applications in Material Handling Tools: **.

1. ** Automated Guided Automobiles (AGVs): ** The KL016004 incorporates seamlessly right into AGVs used for moving heavy containers or resources throughout manufacturing floors. Its high torque capacity and smooth power transmission ensure exact movement, minimizing hold-ups and reducing wear on various other mechanical parts. This enhances AGV uptime and operational effectiveness in high-throughput settings.

2. ** Expenses Cranes and Gantry Systems: ** In container lifting applications, the gearbox core component improves load control and placing accuracy. Its robust design takes care of abrupt load changes and repeated lifting cycles, essential for production line or storage space locations where containers have to be moved safely between stages. The minimized resonance and noise degrees also contribute to a more secure office.

3. ** Conveyor Solutions: ** For making plants relying upon conveyor belts to relocate hefty products, the KL016004 makes sure consistent speed and torque, also under irregular lots. Its energy-efficient layout lowers power usage, straightening with sustainability goals while preserving efficiency in continuous procedures.

4. ** Heavy-Duty Robotic Arms: ** The part’s small yet effective construct makes it perfect for robot arms entrusted with piling or rearranging containers. Its precision sustains programmable activities, reducing mistakes in automated procedures.

** Perks for Manufacturing Plant Kingdoms: **.

The KL016004 prolongs tools lifespan with superior warmth dissipation and corrosion-resistant products, cutting upkeep costs. Its compatibility with smart sensing units allows integration right into IoT-enabled systems, enabling predictive upkeep and real-time performance monitoring. By boosting load-handling accuracy, it reduces safety and security risks and functional downtime, straight boosting output in vehicle, aerospace, and consumer goods markets.

In summary, the KL016004 New Gearbox Core Element is a transformative remedy for product handling systems, offering reliability, effectiveness, and versatility to fulfill the advancing demands of commercial automation. Its applications throughout AGVs, cranes, conveyors, and robotics position it as a keystone of modern production facilities.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of KL016004 New Gearbox Core Component for Container Lifting Transport System in Manufacturing Plants Material Handling Equipment

The KL016004 New Gearbox Core Component is a critical part of container lifting transport systems in manufacturing plants, designed to ensure efficient, reliable movement of heavy loads. Below are answers to five common FAQs about this component:

**What is the KL016004 Gearbox Core Component used for?**

The KL016004 is engineered to manage power transmission within gearboxes used in container lifting systems. It enables smooth lifting, lowering, and horizontal transport of shipping containers in material handling equipment, ensuring precise control under high-stress conditions. It integrates seamlessly with motors and mechanical systems to handle heavy loads while maintaining operational efficiency.

**Is the KL016004 compatible with existing container lifting systems?**

Yes, the KL016004 is designed to meet industry-standard specifications for gearbox components, making it compatible with most container lifting systems. However, users should verify dimensional fit, torque ratings, and mounting requirements against their equipment’s OEM guidelines. Customization options are available for non-standard setups.

**What materials is the KL016004 made from?**

The component is constructed from high-grade alloy steel, heat-treated for enhanced strength and durability. Critical surfaces are coated with anti-wear and corrosion-resistant materials, ensuring longevity in harsh industrial environments, including exposure to moisture, dust, and variable temperatures.

**How often does the KL016004 require maintenance?**

Routine inspections every 500 operational hours are recommended to check for wear, misalignment, or lubrication issues. Lubricant replacement should occur every 1,000 hours. Maintenance frequency may vary based on workload intensity—systems operating near maximum capacity may need more frequent checks.

**What are the performance benefits of upgrading to the KL016004?**

Upgrading improves gearbox efficiency, reducing energy consumption by up to 15% due to optimized gear design. It enhances load distribution, minimizing wear on adjacent parts, and supports higher load capacities with smoother operation. This results in lower downtime, extended equipment lifespan, and improved safety during container handling.

The KL016004 combines durability, compatibility, and performance to streamline material handling operations in demanding industrial settings.

(KL016004 New Gearbox Core Component for Container Lifting Transport System in Manufacturing Plants Material Handling Equipment)

REQUEST A QUOTE

RELATED PRODUCTS

Pharmaceutical Industry Equipment Waterproof Corrosion Resistance VF Stainless Steel Gearbox

Long life AC/DC motor RV reductor gear box right angle gearbox 90 degree worm reducer for conveyor system

Industrial Bevel Gears For Various Industries Used In Gearboxes For Efficient Spur Gear Transmission

Customized AB Serious Helical Gears Planetary Gearbox

Economical Planetary Gearbox Silent Gearbox VRSF Series Injection Molding Industry Dedicated To Various Motors