PRODUCT PARAMETERS

Description

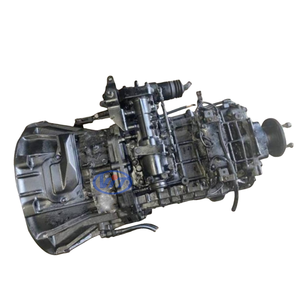

Introduction of NBK Series Helical bevel Speed Gearbox Gear Reducer with 220V 380V 400V 415V 440V 480V AC 3-Phase Electric Motor

NBK Series Helical bevel Speed Gearbox Gear Reducer with 220V 380V 400V 415V 440V 480V AC 3-Phase Electric Motor, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.NBK Series Helical bevel Speed Gearbox Gear Reducer with 220V 380V 400V 415V 440V 480V AC 3-Phase Electric Motor is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of NBK Series Helical bevel Speed Gearbox Gear Reducer with 220V 380V 400V 415V 440V 480V AC 3-Phase Electric Motor

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(NBK Series Helical bevel Speed Gearbox Gear Reducer with 220V 380V 400V 415V 440V 480V AC 3-Phase Electric Motor)

Specification of NBK Series Helical bevel Speed Gearbox Gear Reducer with 220V 380V 400V 415V 440V 480V AC 3-Phase Electric Motor

The NBK Collection Helical Bevel Rate Gearbox Gear Reducer paired with a 3-phase AC electric motor is engineered for high-performance commercial applications needing specific torque transmission and reputable rate reduction. This integrated system incorporates a tough helical bevel gearbox with a durable electric motor, available in voltage ratings of 220V, 380V, 400V, 415V, 440V, and 480V, making sure compatibility with global power standards. The electric motor operates a 3-phase a/c supply, supplying consistent power outcome throughout a large range of commercial atmospheres.

The gearbox features a helical bevel gear layout, maximizing efficiency (approximately 95%) and decreasing noise throughout operation. It uses a broad decrease ratio variety from 5:1 to 100:1, accommodating diverse rate and torque needs. The torque capacity spans as much as 5000 Nm, depending upon the version, making it ideal for heavy-duty machinery. The real estate is created from high-strength cast iron or light weight aluminum alloy, ensuring durability and warmth dissipation. Gears are precision-machined from case-hardened steel, surface-treated for wear resistance and prolonged service life.

The motor is IP55-rated for security against dirt and water access, boosting dependability in rough conditions. It includes Class F insulation, allowing operation at temperatures up to 155 ° C without efficiency deterioration. The electric motor’s power range varies from 0.12 kW to 200 kW, sustaining applications such as conveyors, mixers, crushers, and packaging equipment. Input and outcome shafts are dynamically secured to stop lube leak and contamination. Placing choices include foot-mounted, flange-mounted, or shaft-mounted configurations for adaptable assimilation.

The system is pre-lubricated with high-grade synthetic oil, lowering maintenance requirements. Key functions include smooth start-stop cycles, low resonance, and high overload ability. Compliance with worldwide standards (CE, ISO) makes certain security and high quality. Adjustable alternatives include supporting cooling followers, encoders, or brake systems. Ideal for markets such as mining, food handling, and product handling, the NBK Series provides energy-efficient, low-maintenance efficiency with a compact style to conserve space. Service intervals are expanded due to durable building and construction, lessening downtime and operational expenses.

(NBK Series Helical bevel Speed Gearbox Gear Reducer with 220V 380V 400V 415V 440V 480V AC 3-Phase Electric Motor)

Applications of NBK Series Helical bevel Speed Gearbox Gear Reducer with 220V 380V 400V 415V 440V 480V AC 3-Phase Electric Motor

The NBK Series Helical Bevel Rate Transmission Equipment Reducer, when coupled with 220V, 380V, 400V, 415V, 440V, or 480V AC 3-phase electric motors, delivers high-performance power transmission solutions for commercial and commercial applications. Designed for performance and toughness, this mix is suitable for equipment requiring specific speed decrease, torque amplification, and dependable procedure under heavy loads. The helical bevel gear design ensures smooth, low-noise performance with high torsional tightness, making it ideal for demanding settings.

Usual applications include conveyor systems, where the gear reducer guarantees regular rate control and tons handling in production, mining, and logistics. It is also widely utilized in mixers, agitators, and extruders in chemical, food handling, and pharmaceutical sectors, where variable torque and resistance to extreme problems are vital. Product packaging machinery take advantage of its precision in integrating movements, while material handling devices like cranes, raises, and lifts relies upon its durable torque result for secure training and positioning.

The compatibility with multiple voltage inputs (220V– 480V) enables smooth combination right into international power grids, accommodating varied local requirements. This adaptability makes the NBK Series suitable for international deployments in fields like agriculture, building and construction, and renewable energy. For instance, it powers irrigation pumps, crushers, and wind generator pitch control systems, guaranteeing energy-efficient operation.

Secret benefits include high efficiency (as much as 95%), minimized maintenance because of set steel gears and oil-sealed bearings, and small design for space-constrained installments. The transmission’s modular construction sustains customization of decrease ratios, shaft arrangements, and placing positionings, adjusting to certain machinery needs.

In heavy sectors such as steel manufacturing or cement production, the NBK Collection holds up against extreme temperatures and rough environments, improving devices durability. Its corrosion-resistant coverings and IP-rated sealing safeguard versus dust and dampness, suitable for outside or washdown setups.

By incorporating the NBK Collection Gear Reducer with a 3-phase electric motor, customers achieve optimal energy usage, decreased downtime, and improved performance across fields. Whether for variable-speed operations, high-starting torque needs, or continuous-duty cycles, this system offers a flexible, cost-efficient service for modern industrial difficulties.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of NBK Series Helical bevel Speed Gearbox Gear Reducer with 220V 380V 400V 415V 440V 480V AC 3-Phase Electric Motor

**What voltage configurations does the NBK Series Helical Bevel Gear Reducer with AC 3-Phase Motor support?**

The NBK Series motor operates across multiple voltage inputs, including 220V, 380V, 400V, 415V, 440V, and 480V, making it adaptable to global industrial power standards. Ensure the motor is wired correctly for your local voltage—consult the product manual or a technician to adjust terminal configurations or install a compatible variable frequency drive (VFD) if required.

**How do I install the NBK gearbox and motor?**

Proper installation requires aligning the gearbox with driven equipment shafts to prevent misalignment stress. Securely mount the unit on a flat, vibration-resistant base. Verify lubrication levels before startup and connect the motor to a 3-phase power supply matching the rated voltage. Include safety guards and overload protection to comply with operational standards.

**What maintenance is needed for this gear reducer?**

Routine maintenance includes checking oil levels and replacing lubricant every 3,000–5,000 operating hours or as specified. Inspect seals for leaks, monitor bearing temperatures, and listen for unusual noises. Maintenance frequency depends on workload—heavy-duty cycles may require checks every 3 months, while moderate use can extend intervals to 6 months.

**What applications suit the NBK Series Gear Reducer?**

This unit is ideal for high-torque, low-speed applications such as conveyor systems, mixers, crushers, cranes, and industrial machinery requiring precise speed reduction. Its helical bevel design handles radial and axial loads efficiently, making it suitable for food processing, mining, material handling, and chemical industries.

**How efficient is this gear reducer compared to others?**

The helical bevel gear design ensures over 95% efficiency due to reduced friction and smoother tooth engagement. This outperforms worm gear reducers (typically 50–90% efficiency), lowers energy consumption, and minimizes heat generation. The precision-machined gears enhance durability, reducing downtime and operational costs in continuous-use environments.

(NBK Series Helical bevel Speed Gearbox Gear Reducer with 220V 380V 400V 415V 440V 480V AC 3-Phase Electric Motor)

REQUEST A QUOTE

RELATED PRODUCTS

PLF Planetary Gearbox Motor Reducer Speed With Ratio 1:3 1:5 1:10 1:15 1:20 1:25 1:50 1:100

Pharmaceutical Industry Equipment Waterproof Corrosion Resistance VF Stainless Steel Gearbox

Hot ing Mub1308tm1 Cylindrical Roller Needle Bearings Single Row Oil Lubricated Gearbox For Machinery

Ready-to-Ship Used Hitachi ZAXIS 200 Excavator Doosan Engine Core Japanese Farm Machinery Hitachi 120 Pump Gearbox

High Quality MT78Q-SAL20T L017101016BA0 Steel Gearbox New Condition for Foton Light Duty Trucks