PRODUCT PARAMETERS

Description

Introduction of New Type T Series Spiral Bevel Gear For Transmission Machine Angular gearbox Speed Increasing gearbox

New Type T Series Spiral Bevel Gear For Transmission Machine Angular gearbox Speed Increasing gearbox, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.New Type T Series Spiral Bevel Gear For Transmission Machine Angular gearbox Speed Increasing gearbox is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of New Type T Series Spiral Bevel Gear For Transmission Machine Angular gearbox Speed Increasing gearbox

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(New Type T Series Spiral Bevel Gear For Transmission Machine Angular gearbox Speed Increasing gearbox)

Specification of New Type T Series Spiral Bevel Gear For Transmission Machine Angular gearbox Speed Increasing gearbox

The New Kind T Collection Spiral Bevel Gear is engineered for high-performance transmission machines, angular transmissions, and speed-increasing transmissions, offering precision, sturdiness, and efficiency. Created from state-of-the-art alloy steel such as 20CrMnTi, these equipments undertake innovative heat treatment processes, including carburizing, quenching, and tempering, to attain a surface area hardness of 58-62 HRC and a core toughness of 30-35 HRC. This makes certain extraordinary wear resistance and load-bearing capacity. The spiral tooth style makes it possible for smooth, peaceful procedure with minimized vibration, making them optimal for high-speed applications. Gear proportions range from 1:1 to 1:6, accommodating both speed-increasing and torque-multiplying setups. Maximum torque capability covers 50 Nm to 5000 Nm, depending upon gear dimension and product specs. Input speeds can rise to 5000 RPM, with output speeds adjusted proportionally via the equipment ratio. Operating performance surpasses 95%, reducing energy loss. Precision-machined to ISO 23509 and AGMA 2005 criteria, the gears make certain minimal backlash (under 10 arc-minutes) for precise power transmission. Installing options consist of flange, foot, and shaft arrangements for versatile integration. Lubrication is maximized for oil bathroom or flowing systems, with sealed housing designs using nitrile rubber to prevent leaks and contamination. Operating temperature levels vary from -20 ° C to 120 ° C, suitable for extreme environments. Applications include industrial machinery, auto systems, aerospace actuators, marine propulsion, and heavy-duty mining devices. Personalization is offered for equipment proportions, dimensions, materials, and surface coverings like zinc or nickel plating for rust resistance. Strenuous testing consists of dimensional examinations, vibrant tons screening, and noise-level assessments (listed below 75 dB under full tons). Designed with a safety aspect of 1.5 x ranked load, these equipments comply with ISO 9001 and CE standards, making certain integrity and longevity in demanding problems.

(New Type T Series Spiral Bevel Gear For Transmission Machine Angular gearbox Speed Increasing gearbox)

Applications of New Type T Series Spiral Bevel Gear For Transmission Machine Angular gearbox Speed Increasing gearbox

The New Type T Collection Spiral Bevel Gear is a sophisticated solution developed for high-performance transmission systems, providing unmatched effectiveness, sturdiness, and accuracy in angular power transfer applications. Engineered with sophisticated spiral bevel modern technology, this gear series excels in sending torque between intersecting shafts at 90-degree angles, making it excellent for usage in transmission equipments, angular gearboxes, and speed-increasing gearboxes throughout markets. Its maximized tooth geometry makes sure smooth involvement, lowered noise, and minimal vibration, even under hefty tons or high-speed problems.

In transmission machines, the T Collection equipment boosts power distribution in durable equipment such as mining machinery, building cars, and commercial conveyors. Its robust building enables it to handle severe shock lots and variable operating speeds while keeping regular performance. For angular transmissions, the gear’s spiral bevel layout enables effective power transfer in applications needing directional adjustments, such as marine propulsion systems, farming equipment, and robotics. The precise positioning and high surface area coating of the equipment teeth reduce power loss, enhancing general system performance.

Speed-increasing gearboxes benefit substantially from the T Series equipment’s capability to run at raised RPMs without jeopardizing integrity. This makes it a recommended choice in wind generator drivetrains, aerospace systems, and high-speed pumps, where quick velocity and deceleration are crucial. The equipment’s heat-treated alloy steel building and construction makes sure resistance to use, matching, and deterioration, expanding life span in rough environments.

Adjustable to fulfill particular torque, speed, and installing demands, the T Collection sustains modular assimilation with existing systems. Its portable style conserves space in densely packed equipment, while sophisticated lubrication channels boost thermal management. Suitable for sectors varying from auto to renewable resource, the New Kind T Series Spiral Bevel Gear provides an affordable, low-maintenance option for optimizing power transmission efficiency and functional uptime.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of New Type T Series Spiral Bevel Gear For Transmission Machine Angular gearbox Speed Increasing gearbox

The New Type T Series Spiral Bevel Gear is designed for high-performance transmission systems, particularly in angular gearboxes and speed-increasing gearboxes. Below are five common FAQs with direct answers:

**1. What applications is the T Series Spiral Bevel Gear suited for?**

The T Series is ideal for industries requiring precise power transmission between intersecting shafts at 90-degree angles. Common uses include automotive differentials, industrial machinery, wind turbines, and high-speed equipment like pumps or compressors in energy and aerospace sectors. Its design supports speed-increasing configurations, making it suitable for systems needing rapid RPM boosts.

**2. What are the key advantages of this gear over straight bevel gears?**

Spiral bevel gears offer smoother, quieter operation due to gradual tooth engagement, reducing vibration and shock loads. The T Series enhances this with hardened alloy steel construction, high torque capacity, and optimized tooth profiles for minimal backlash. This ensures durability in high-load, high-speed environments and extends service life compared to straight bevel gears.

**3. How do I maintain the T Series gear for optimal performance?**

Regular lubrication with high-viscosity synthetic oil is critical to minimize wear. Inspect gears every 500–1,000 operational hours for alignment, tooth damage, or pitting. Avoid overloading and ensure proper ventilation in the gearbox to prevent overheating. Follow the manufacturer’s maintenance schedule for seals and bearings.

**4. Can the gear ratio or dimensions be customized?**

Yes. The T Series supports customization in gear ratios, shaft sizes, and mounting configurations to fit specific machinery requirements. Material upgrades (e.g., corrosion-resistant coatings) and heat treatment options are available for extreme operating conditions.

**5. What efficiency can I expect from this gear system?**

Efficiency ranges between 95–98% under optimal conditions. Precision grinding of spiral teeth reduces friction, while proper alignment and lubrication minimize energy loss. Efficiency may vary slightly with load intensity, speed, and ambient temperature, but the design prioritizes minimal power waste in speed-increasing setups.

(New Type T Series Spiral Bevel Gear For Transmission Machine Angular gearbox Speed Increasing gearbox)

REQUEST A QUOTE

RELATED PRODUCTS

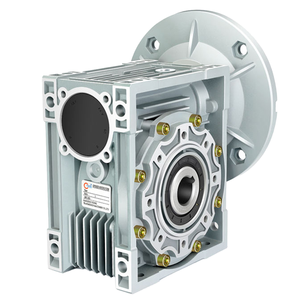

Ynmrv Series 0.06-15kw Worm Gearbox Flange Output Motor Aluminium Gear Box Reducer

Factory Manufacture RV Series High Torque Worm gearbox Right Angle Gearbox With Low Output Speed Reducer

Factory Slow Down Square High Hardness High Precision Aluminum Alloy Gearbox

Howo double H valve WG2203250003 Sinotruk HOWO truck howo gearbox spare parts