Gearbox

TILI K Series K87 4KW Direct Connection Vertical Shaft Gearbox Heavy Duty Helical Bevel Gearbox Industrial Gearbox

twin extruder gearbox for mini filament extrusion line

1HZ Transmission Gearbox For Toyota Landcruiser 1HZ HZJ 78 79 Series R151F Transmission 4*4 33030-6A410/33030-6A411/33030-6A412

Gear s Plastic gears Spur gears for gearbox drives

Worm Gearbox 48v 1 Kw Second Hand Speed Reducer With DC Motor Worm Gearbox For Conveyor

0AM DQ200 Automatic Transmission DSG 7speed Remanufactured AutoTransmission Gearbox

DIWAGER Right Angle Bevel gearbox Planetary Gearbox Corner Planetary Gear Reducer High Precision Low Backlash

Electric Toy Car Plastic Gearbox for RC Parts Plastic RC Car Motor Gearbox Accessory

S Series Solid Shaft Helical Worm gearbox Tractor Pto Multiplier gearbox 0.12kw-22kw gearbox Marine Transmission 11Nm – 4530Nm

50mm planetary gearbox with 50srz high-speed BLDC motor 35W 12v24v brushless DC speed regulating motor

K Series Bevel Helical gearbox Bevel Gear Box Reducer Reductor Stm 100 ( 90 – B5 ) Bevel gearbox Rack Pinion Lift Motor

Factory Slow Down Square High Hardness High Precision Aluminum Alloy Gearbox

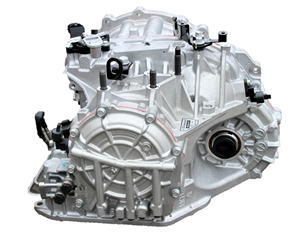

Introduction of Mine Heavy Machinery Gearbox

Mining heavy machinery gearboxes are crucial elements utilized in various mining tools to transfer mechanical power from the engine or motor to the device's moving parts. These gearboxes are designed to deal with high torque and lots, guaranteeing reliable operation under extreme conditions such as dust, wetness, and temperature level variations. They play an essential duty in enhancing the performance and productivity of mining procedures.

Functions of Mine Heavy Machinery Gearbox

- High Torque Capability: Created to deal with significant mechanical forces without jeopardizing performance.

- Durable Construction: Made from durable materials like hardened steel and special alloys to hold up against extreme atmospheres.

- Effective Power Transmission: Maximized for minimal power loss throughout power transmission.

- Sealed Style: Shields against dust, particles, and wetness, prolonging transmission life expectancy.

- Modification Options: Readily available in different dimensions and configurations to meet details application needs.

Specifications Table of Gearbox

| Parameter | Standard Model X1 | Standard Model X2 | High Torque Y1 | High Efficiency Z1 |

|---|---|---|---|---|

| Ratio Range | 3:1 to 10:1 | 5:1 to 20:1 | 3:1 to 15:1 | 10:1 to 30:1 |

| Input Speed (RPM) | Up to 3000 | Up to 4000 | Up to 2500 | Up to 5000 |

| Output Torque (Nm) | 50 to 200 | 100 to 500 | 200 to 800 | 50 to 300 |

| Efficiency (%) | 90% | 88% | 85% | 92% |

| Mounting Position | Any | Horizontal/Vertical | Horizontal | Vertical |

| Lubrication Type | Oil Bath | Oil Bath | Grease | Oil Bath |

| Weight (kg) | 15 | 25 | 30 | 20 |

| Material | Cast Iron, Steel | Cast Iron, Steel | Cast Iron, Alloy Steel | Aluminum Alloy, Steel |

| Noise Level (dB) | ≤70 | ≤75 | ≤80 | ≤68 |

| Environmental Protection | IP65 | IP65 | IP67 | IP65 |

Applications of Mine Heavy Machinery Gearbox

- Excavators: Facilitate the motion of the arm and pail for excavating and loading.

- Excavators: Make it possible for the blade to press and move large amounts of planet and rock.

- Loaders: Assist in training and moving materials into trucks or various other transportation vehicles.

- Drilling Rigs: Make specific precise and effective rotations for piercing via sturdy rock developments.

- Conveyors: Drive the belts that transfer mined products over long distances efficiently.

Company Introduction

Gearbox Solutions is in exporting high-performance gearboxes worldwide. Our commitment to quality and innovation ensures our products meet international standards. With a diverse portfolio including planetary, helical, and worm gearboxes, we cater to automotive, industrial, and renewable energy sectors. Our technical team provides exceptional customer service, offering tailored solutions to meet specific needs. Located in Frankfurt, Germany, we pride ourselves on delivering durable, efficient gearboxes that enhance machinery performance globally. Join us for unparalleled reliability and excellence in power transmission.

5 Frequently Asked Questions of Mine Heavy Machinery Gearbox

What materials are mine heavy machinery gearboxes constructed from? Transmissions are typically made from solidified steel or specialized alloys that use high strength and sturdiness.

Just how usually should a transmission be serviced?

Regular maintenance is advised every 3 to 6 months, depending upon use and environmental problems. Evaluations include looking for wear, leakages, and correct lubrication.

Can a gearbox be repaired if it stops working?

Minor concerns can often be repaired by changing damaged parts such as bearings or seals. Nonetheless, severe damage might call for a total replacement.

Are customized transmissions readily available for specific equipment

Yes, numerous makers provide customized transmission services customized to fit unique operational requirements and specifications.

What are the indications of a failing transmission?

Typical signs consist of uncommon sounds (grinding, clunking), resonances, difficulty moving equipment, and excessive heat or oil leakages. Early discovery and repair services can avoid disastrous failure.