PRODUCT PARAMETERS

Description

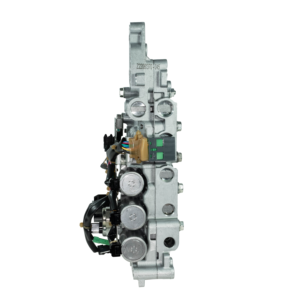

Introduction of RV Series Involute Spur Reducer Ratio130 Gearbox Transmission Worm Reduction Gearbox

RV Series Involute Spur Reducer Ratio130 Gearbox Transmission Worm Reduction Gearbox, or gearbox, is an important part of a mechanical transmission system, mainly used to change the speed and torque between the engine output shaft and the drive wheels. It realizes the selection of different ratios through the meshing of a series of gears to adjust the speed and strength of the power transmission.RV Series Involute Spur Reducer Ratio130 Gearbox Transmission Worm Reduction Gearbox is not only used in automobiles but is also very common in industrial equipment, agricultural machinery, construction machinery, and other applications that require the adjustment of speed and torque.

Features and benefits of RV Series Involute Spur Reducer Ratio130 Gearbox Transmission Worm Reduction Gearbox

Multi-stage gearing: Multiple gear options are available, allowing speed and torque to be optimized based on load conditions.

Increased Efficiency: Proper gear ratios maximize engine efficiency and reduce fuel consumption.

Enhanced Performance: Provides optimal power output under different operating conditions, improving the overall performance of the equipment.

Protect the engine: Reduce the burden on the engine by adjusting the gear ratio to avoid overloading.

Smooth operation: Using synchronizers and other technologies to ensure smooth gear shifting and reduce shock and noise.

Durability: High-quality materials and precision manufacturing processes ensure a long service life.

(RV Series Involute Spur Reducer Ratio130 Gearbox Transmission Worm Reduction Gearbox)

Specification of RV Series Involute Spur Reducer Ratio130 Gearbox Transmission Worm Reduction Gearbox

The RV Series Involute Spur Reducer Ratio130 Transmission Worm Reduction Transmission is engineered for high-performance industrial applications requiring precise torque transmission and trusted speed reduction. This transmission combines involute spur tailoring with a worm drive mechanism to deliver a high reduction ratio of 130:1, making it ideal for sturdy equipment, conveyor systems, mixers, and material handling equipment. Created from high-strength alloy steel for equipments and set worm shafts, it makes certain toughness under continual operation and high-load problems. The housing is constructed from durable actors iron, giving superb heat dissipation and resistance to mechanical anxiety.

The transmission includes a compact design, enhancing room performance while keeping a high torque ability of approximately 10,000 Nm, depending on arrangement. Its involute spur teeth profile ensures smooth, low-noise meshing and improved power transmission performance, while the worm decrease stage supplies self-locking abilities for safety and security in vertical or inclined applications. Input and outcome shafts are precision-machined for smooth combination with electric motors, pumps, or driven tools, supporting both straight and vertical mounting orientations.

Trick requirements consist of an input rate series of 1,500– 3,000 RPM, operating temperature level range of -20 ° C to 80 ° C, and IP65 protection for dust and water resistance. Lubrication is pre-filled with artificial grease, extending maintenance periods to 8,000– 10,000 hours. The transmission is compatible with IEC-standard motors and consists of personalized flanges or shafts to fulfill diverse application needs.

Applications span sectors such as mining, construction, food processing, and renewable resource, where high torque, precision, and integrity are essential. The RV Series is CE-certified and evaluated for vibration, noise, and tons endurance, making sure compliance with international criteria. Backed by a 12-month service warranty, it supplies an affordable solution for reducing downtime and enhancing functional performance in demanding atmospheres. Optional accessories include cooling fans, torque arms, and encoder adapters for specialized arrangements.

(RV Series Involute Spur Reducer Ratio130 Gearbox Transmission Worm Reduction Gearbox)

Applications of RV Series Involute Spur Reducer Ratio130 Gearbox Transmission Worm Reduction Gearbox

The RV Series Involute Spur Reducer Proportion 130 Transmission Worm Reduction Transmission is a high-performance mechanical option designed to supply accuracy, longevity, and efficiency popular commercial applications. Combining involute spur tailoring with worm decrease innovation, this transmission uses a robust 130:1 decrease proportion, making it suitable for systems calling for high torque result, smooth operation, and compact design. Its innovative design ensures reliable power transmission while lessening power loss, noise, and resonance.

** Trick Applications: **.

1. ** Industrial Equipment: ** Perfect for conveyor systems, mixers, and packaging equipment, where regular torque and regulated rate are important. The 130:1 ratio makes it possible for exact movement control in heavy-load situations.

2. ** Material Handling: ** Made use of in cranes, hoists, and lift systems, the transmission’s high torque ability makes certain secure lifting and positioning of hefty materials.

3. ** Automation & Robotics: ** Supplies exact speed decrease for robotic arms and automated production line, boosting precision in repeated tasks.

4. ** Farming & Construction: ** Supports equipment like tractors, excavators, and farmers by dealing with high shock tons and severe operating conditions.

5. ** Renewable resource: ** Incorporates right into wind turbine pitch systems and solar monitoring systems, supplying reputable efficiency in variable environmental conditions.

** Features & Conveniences: **.

– ** Involute Spur Gearing: ** Makes certain smooth meshing, lowered wear, and prolonged life span compared to traditional equipment layouts.

– ** Worm Reduction Device: ** Provides high torque reproduction in a portable impact, ideal for space-constrained setups.

– ** Resilient Construction: ** Made from set steel gears and corrosion-resistant housings, it stands up to sturdy usage and harsh environments.

– ** Low Upkeep: ** Secured bearings and premium lubes reduce downtime and functional prices.

– ** Energy Effectiveness: ** Maximized gear geometry decreases rubbing, enhancing total system effectiveness.

** Versatility: ** The gearbox is compatible with electrical motors, hydraulic systems, and diesel engines, providing flexibility throughout industries. Adjustable installing alternatives and shaft setups ensure smooth integration right into existing arrangements.

** Why Pick This Transmission? **.

The recreational vehicle Collection Gearbox balances power, accuracy, and dependability, making it a cost-efficient option for sectors seeking to boost productivity and reduce mechanical failures. Whether for heavy equipment, precision automation, or renewable energy systems, its 130:1 proportion and sturdy style make sure consistent performance under severe tons. Purchase this transmission to enhance operational performance, lower upkeep demands, and attain long-lasting reliability in your applications.

Company Introduction

Established in 2009, Gearbox Solutions Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of RV Series Involute Spur Reducer Ratio130 Gearbox Transmission Worm Reduction Gearbox

What is the reduction ratio of the RV Series Involute Spur Reducer Ratio 130 Gearbox? The reduction ratio of 130:1 means the input shaft rotates 130 times for every single rotation of the output shaft. This high ratio is ideal for applications requiring significant speed reduction and torque multiplication, such as heavy-duty machinery, conveyor systems, or industrial mixers where controlled, low-speed power transmission is critical.

What applications is this gearbox suitable for? This gearbox is designed for heavy-load, low-speed scenarios requiring high torque output. Common applications include material handling equipment, packaging machinery, construction equipment, and agricultural machinery. Its robust construction (typically cast iron housing and hardened steel gears) ensures durability in harsh environments, making it suitable for industries like mining, manufacturing, and wastewater treatment.

How efficient is the RV Series worm reduction gearbox? Worm gearboxes generally have lower efficiency (around 60-90%) compared to helical or planetary gearboxes due to sliding friction between the worm and wheel. However, the involute spur gear design in this model improves meshing efficiency. Efficiency also depends on lubrication quality, load conditions, and proper alignment. Regular maintenance can help sustain optimal performance.

What maintenance does this gearbox require? Maintenance includes periodic lubrication checks and replacements using high-viscosity mineral oil or synthetic lubricants specified by the manufacturer. Inspect seals for leaks, monitor gear and worm wear, and ensure proper alignment with connected equipment. Overheating or unusual noise should prompt immediate inspection. Dusty or wet environments may require more frequent servicing to prevent contamination.

Can this gearbox handle bidirectional operation? Yes, the RV Series worm gearbox supports bidirectional rotation. However, worm gearboxes are inherently self-locking in one direction (when the worm drives the wheel), preventing back-driving. This feature adds safety in applications like hoists or lifts where unintended reverse movement must be avoided. If bidirectional power transmission is needed, ensure the motor is sized to overcome the self-locking tendency in the reverse direction.

(RV Series Involute Spur Reducer Ratio130 Gearbox Transmission Worm Reduction Gearbox)

REQUEST A QUOTE

RELATED PRODUCTS

Aokman S Series Worm Gear Speed Reducer High Performance Gearbox with Output Flange

Worm Gearbox Manufactory NMRV40 Worm Gear Speed Reducer 14mm Input Shaft Diameter

Spur Planetary Gearbox PLE Series Planetary Reducer Speed Planetary Gearbox With High Torque & High Precision

Factory direct s quality gearbox DF6S650 1700010-KJ404 original factory gearbox for Tianjin Dongfeng

200~1000 Rpm MB Series Speed Variator Reduction gearbox